ID Fan static Head Draft Loss in Boiler Duct Dust collector 150 50 50 mm WC. Books On Idfd Fan Design Calculations - posted in Industrial Professionals.

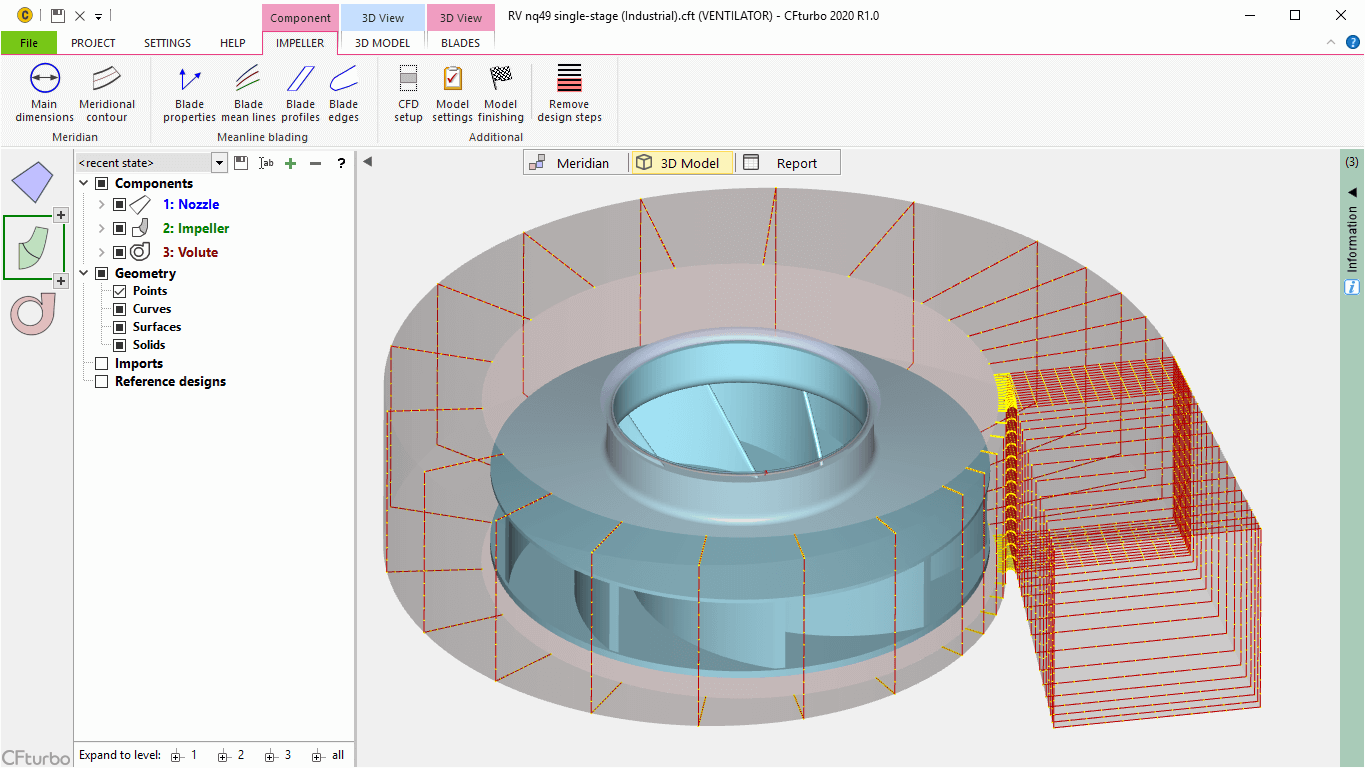

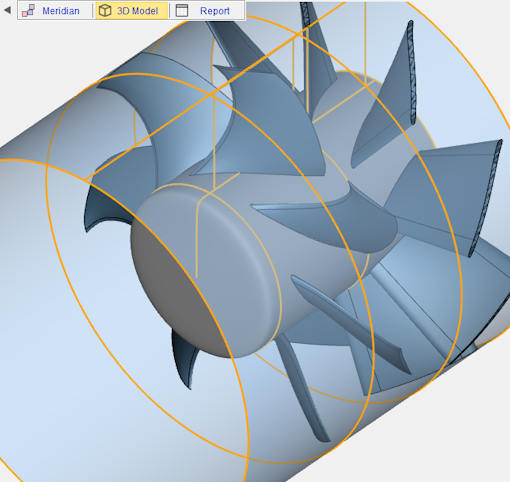

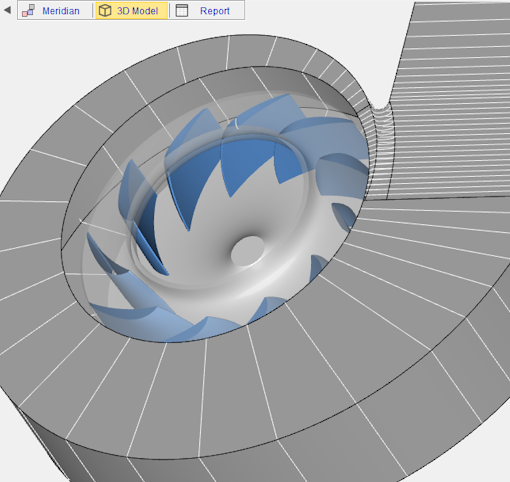

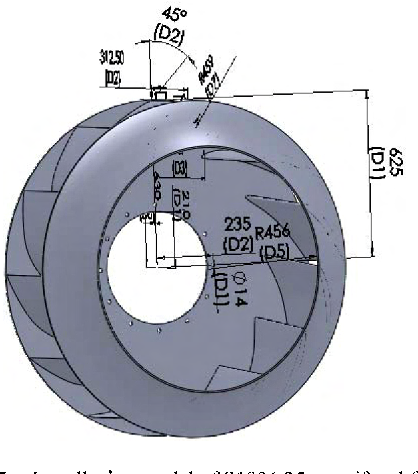

Software For The Design Of Fans Blowers

All of which have individual benefits volume pressure speed power efficiency etc but all of them will shift.

. ID Fan Design Calculations- Equations. The grid topology used for the impeller design calculation shown in Figure 5 was maintained. Learn more and request a free quote for your induced fan application.

Fan total pressure FTP is the increase in total pressure pt measured by facing pitot tubes across the fan FTP pt2 pt1 101 Fan velocity pressure FVP is the average velocity. Ad AirPro builds heavy-duty high-temp industrial fans for induced draft applications. We at Thermodyne design manufacture supply both Induced and Forced Draft fans for your system.

Im trying to get some help doing a rough estimate calculation of the volumetric flow through and induced draft fan on a balanced draft unit without doing a performance test. Suitable for higher static pressure up to 14 35 KPa. Please do suggest on the same.

Ad AirPro builds heavy-duty high-temp industrial fans for induced draft applications. ID Fan Motor Power Calculator. PE 0 and Q 0 because fans are designed to overcome.

Fans fall into two general categories. Centrifugal flow and axial flow. 9 to 16 blades of airfoil curved away from the direction of rotation.

During the performance analysis of ID fan the following parameters are measured for analyses. Sizing calculations of Boiler Pumps and ID FD Fans. We have also developed an online calculator for the customers for calculating the.

Approximate 250 mmWC Taking 20 margin on head ID Fan head 250 12 300 mm WC. About Steam boiler steam and drawing thermodynamics steam table Know about some things Boiler Math solution Energy conservation thermodynamic therma. Online Induced Draft ID Fan Motor Power Calculator.

Effect of axial gap between inlet nozzle and impeller on efficiency and flow pattern in centrifugal fans numerical and experimental. For a coal fired boiler an ID fan is used for controlling the draft. Fan efficiencies differ from design to design and also by types.

Learn more and request a free quote for your induced fan application. Sample sizing calculations for BFW pumps and Fans for a typical Coal fired Boiler generating steam of 50000 Kghr at 67. There are a number of fan types.

Typical ranges of fan efficiencies are given in Table 52. Pneumatic conveying and other industrial process work Head Calculations 1 2 suction discharge For a fan Z 0. The highest speed of the centrifugal fans.

Fan Laws and Fan HP Sizing. Performance Calculations 8 Fan Control 10 Fan Systems 11 Fan Selection Procedure 12 Process Data Sheet 15 APPENDIX A 16 APPENDIX B 18 APPENDIX C 20 APPENDIX D 22 APPENDIX E. So from this performance calculation of ID fan a better design of a fan has been proposed to improve the plant efficiency and save the energy for global interest.

Induced Draft ID Fan is used to draw the flue gases from the system generated from the combustion. Determine Required Air Flow Using Calculations K. The ID fan problems have arisen from the bearing lubrication system which provides oil recirculation to the induction motor bearings and fan main shaft bearings.

Coefficient 005 V K Q T-U S Sf 005 1200 10-5 242 2 108 m3min 381 CFM Determine Required Air Flow Using a. Sheet Filename Title. Depending on the number of blades designed for each fan the total impeller grid.

Coal flow to the boiler. Fan Data RPM Motor Sheave Dia Fan Calculation authored and generated by CTC Design Inc. Impeller axial centrifugal Sirocco etc.

Hobi Elektronika Inversor Kumpulan Rangkaian Perubah Tegangan Aki Dc 12v Menjadi Listrik Ac 220v Rangkaian Elektronik Listrik Hobi

Software For The Design Of Fans Blowers

High Design Requirements Of Motexo Centrifugal Fan Centrifugal Fan Higher Design Ventilation Fans

Abstract Abstraction Engineering Gear Gears Machine Mechanical Mechanism Meta Mechanical Engineering Projects Mechanical Engineering Mechanical Design

Software For The Design Of Fans Blowers

Rumus Perhitungan Bentangan Plate Screw Conveyor Dust Collector Calculation Youtube Teknik Alat Produksi Perkakas

Oem Replacement Impellers Continental Fan Industrial Fan Rapid Prototyping Centrifugal Fan

Figure 4 From A Digital Design Method Of Geometric Model For Centrifugal Fan Impeller Based On Solidworks And Vb Semantic Scholar

0 comments

Post a Comment